You are currently browsing Perun moto international store. If you are from the EU, please visit www.perunmoto.eu

Menu

-

- Home

- Instructions

- Blog

- Sale!

-

Important Information

-

Products

- KTM 390 Adventure (R or X) / Enduro

- 2008-2018 KTM 690 Enduro R / SMC R

- 2019+ KTM 690 Enduro R/SMC R / GasGas ES/SM 700

- KTM 790/890 Adventure (R)

- 2013-2020 KTM 1X90 Adventure (R)

- 2021+ KTM 1290 Super Adventure (R/S)

- Husqvarna 701 Enduro / Supermoto

- Husqvarna Norden 901

- Yamaha Tenere 700

- Ducati DesertX

- Aprilia Tuareg

- BMW F900GS

- BMW R1300GS

- CF-Moto MT450

- "Universal" products

-

You are currently browsing Perun moto international store. If you are from the EU, please visit www.perunmoto.eu

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

KTM 690 Enduro and Husqvarna 701 tank bolts issue explained

October 26, 2016 6 min read 11 Comments

UPDATE, May 2022 - under the red plastics, regarding the frame, GasGas ES/SM 700 is the same bike as 2019+ KTM 690. So all this applies to the GasGas too.

---

There is a lot of information on the "tank bolt" issue on KTM 690 Enduro and younger Husqvarna 701 Enduro, but most of it is scattered over internet. Also, some things changed during the years, so I decided to summarize all info.

1. FUEL TANK = SUB FRAME (on 690/701)

Sub frame is rear part of motorcycle's structure and it usually supports the seat, tail, silencer and all stuff on the back of the bike. Here is how it looks on one of EXC's.

Larger dual sport and adventure bikes have beefier sub frames in order to support pillion and more luggage. Here is how BMW did it on 1200 GS.

Some sub frames are made of aluminum, some of steel. Aluminum ones are lighter, but steel ones can be repaired (welded) more easily. Speaking of repairs, it is worth noting that many dual sport and adventure bikes have problems with sub frames, when they are used as any adventure bike should be used - off road and loaded. Reason for that is that all that luggage is usually carried all the way back, making too big leverage. And when that luggage starts to bounce up and down on the rough tracks, stress on the sub frame can become to much to handle.

KTM took different approach on 690 Enduro - plastic fuel tank is acting as sub frame.

Husqvarna remodeled both frame and fuel tank for 701 Enduro, but principle remained the same. Also, lots of tank-frame components are shared between 690 and 701.

This solution is not bad at all - savings are made both on space and weight. Also, weight distribution is good, since fuel is stored lower. Also, fuel tank itself proved to be very durable. After many years of exploitation, I am not aware of broken or cracked fuel tank on 690.

2. PROBLEM

However, one problem may arise. Fuel tank is connected to trellis frame on four points - two upper and two lower tank bolts. And upper bolts may snap.

But, even when/if this happens on a ride, it is usually easy to do some kind of roadside (or trailside) repair and to limp to safety of civilization or even continue an adventure, depending on rider's repairing skills and available hardware (bolts, washers etc.). And none of essential and expensive components (frame, tank) are likely to be damaged.

Also, this is not something that happens often, I know more than few 690's that are ridden very hard and never had upper bolt failure. Remember, this bike is designed to carry a pillion. So it can support weight.

3. CAUSE

Upper bolts snapping is caused by two things: inferior material of OEM upper bolts and too soft lower bushings.

A. Lower bolts

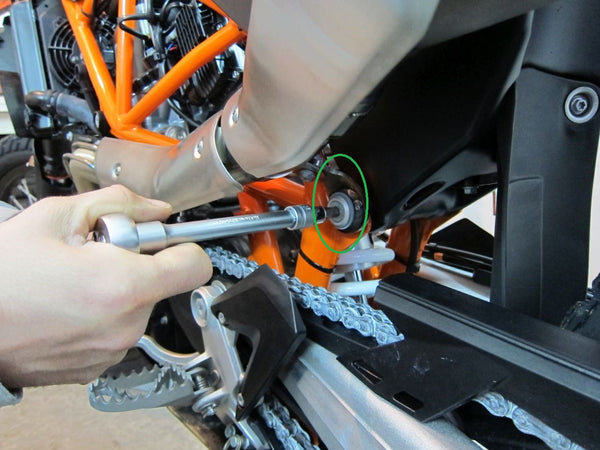

There is through hole on the lower part of fuel tank. Inside that hole there are two rubber bushings (yellow arrow), one at each side. Stainless steel sleeve, with internal thread, is located inside the bushings (green arrow).

On each side, tank is secured to the frame using an M8 bolt. On 2014-on models, on the exhaust side there is countersunk bolt and countersunk washer, used to hold lower silencer bracket too. Countersunk bolt is used to keep low profile so chain is clear at all times. On 2008 - 2013 models there is no lower exhaust bracket, so hex head/torx bolt is used on this side too.

On the opposite side there is just one hex head/torx bolt. Remember, both bolts are bolted into stainless steel sleeve.

This is how OEM lower assembly of 2014-on KTM 690 Enduro and Husqvarna 701 looks like:

And here is how OEM lower assembly of 2008 bike looks like:

So, what is the problem here? Well, to put it simple - rubber bushings. Bushings are too soft so tank move too much under the load. This gets worse on rough roads. KTM did few upgrades of lower rubber bushings, last time somewhere in 2013, but the problem remained.

Also, since two bolts are bolted into one sleeve, it can be tricky to remove both bolts, since sleeve just spins after first bolt is removed. Luckily, on newer models, there is hex slot inside the sleeve, so allen key can be used to prevent sleeve from rotating while other bolt is removed.

B. Upper bolts

On each side of the upper part of fuel tank a hole is located, with rubber bushings inside.

KTM made custom bolts for upper joint points. Nice looking piece of hardware, but not up for the job - it is made of stainless steel which can snap under heavy load. One on the picture is fine, but red arrow show where those bolts snap.

OEM upper bolt is inserted through the rubber bushing and bolted to the frame tab.

C. Base line

So, under heavy load and on rough roads, soft lower tank bushings allow tank to move too much. That movement is transferred to upper bolts, leading to upper bolt snapping.

4. SOLUTION

There are only two aftermarket solutions available on the market, to my best knowledge. Both work really well. I will explain mine:

KTM 690 / HUSQVARNA 701 SUB FRAME (TANK) REINFORCEMENT KIT

KTM used rubber bushings to ensure some elasticity in tank - frame joints. This is done to reduce hard hits and to even distribution of forces acting on tank. This feature is not to be eliminated. So, upper rubber bushings are kept. But design of upper tank bolt is changed. Instead of one custom bolt, we made two piece design - bolt cap and bolt.

Bolt cap is made of much stronger material - it is machined out of AISI 4140 steel and it is heat treated for even more strength. Zinc coating is applied to prevent rust. 'Head' of the bolt cap is only 4 mm, so plastic fairing that is mounted over it stays in its place and doesn't stick out. Size of the 'head' is 27 mm, same as front axle bolt, so no special tools are required. Our bolt cap is not so nice looking as shiny OEM bolt, but is it many times stronger.

And instead of threaded piece sticking out of OEM custom bolt, we provide M8x25 hex head bolt in 12.9 class - strongest commercially available bolt class. Bolt is inserted from the inside, and it is bolted into Perun moto bolt cap. This provides strong frame - tank connection. And remember, upper rubber bushings are kept, so dampening effect remains.

On the lower part of the assembly, soft rubber bushings are replaced with strong polyamide bushings. Material is polyamide with molybdenum, so it can't stuck in the tank hole, even after few years of use.

OEM sleeve with internal thread and two OEM bolts are replaced with one sleeve and one long bolt. Perun moto sleeve is also made of stainless steel, so it won't rust under any circumstances. Long bolt is 10.9 hex head or allen head bolt, depending on the model year of the bike (2008 - 2013 - shorter allen head bolt, 2014-on - longer countersunk bolt).

5. RESULT

What we accomplished with all this:

- no more excessive free play in lower joint,

- much stronger upper joint,

- much easier to remove lower bolt.

Since 'head' of upper bolt is only 4 mm, side fairings are not sticking out. And since countersunk bolt is used on 2014-on models, chain won't interfere with the bolt under any way.

6. SUMMARY

Is this upgrade really needed?

As I mentioned before, I know of more than few 690's with OEM bolts that are alive and well after few years of abuse. I also know for few cases of bolt snapping. If bike is to be used on the paved roads, I doubt this improvement is necessary. If bike is to be used on unpaved roads, without luggage, I guess there is big chance that this upgrade is not really necessary. If bike is to be used on unpaved roads with luggage or on harder terrains I believe this upgraded is needed, for piece of mind at least.

Is this 'install and forget' solution?

Yes and no. Whatever aftermarket solution is chosen, OEM upper rubber bushings should be inspected from time to time. They can deform, causing too much free play in upper joints. Usually, it is never needed to replace them, but there are reported cases of deformed upper bushings, so quick check from time to time is advised. It is easy and cheap to replace them. Otherwise no maintenance is needed.

Also, it is worth noting that even improved upper bolts may snap, under extraordinary circumstances - way too much luggage, hard boxes installed to far to the back, racing through desert loaded with luggage etc. This happens very, very rare (3 cases in more than 500 sets) but it can happen. Rational and logical thinking while preparing the bike for a race or while packing for an adventure is always needed.

11 Responses

Thao Dao

October 20, 2025

How can I buy lower bolts replacement for my Husq 701 Enduro 2022 ?

emergemarketing

June 30, 2025

Thanks for shedding light on this common tank bolt issue with the KTM 690 and Husqvarna 701!Vibration-related bolt failures are a serious concern in off-road bikes. Using high-strength stud bolts or upgraded fastener solutions can really improve reliability and peace of mind on longer rides. Appreciate the detailed explanation and fixes!

Gliga - Perun moto

March 14, 2025

Hi Angel. 690/701 tanks are built tough. Surface scratches should not have any effect on durability or integrity of the tank.

Angel

March 13, 2025

Hola,he arañado superficialmente el depósito de gasolina.No parece que pierda.Lo que quiera saber es si es grueso el depósito

Angel

March 13, 2025

Hello, I have scratched the surface of the tank. It does not leak gasoline. What I want to know is if it is a thick tank.

Angel

March 12, 2025

Hello, I have scratched the surface of the tank. It does not leak gasoline. What I want to know is if it is a thick tank.

Nikola

May 22, 2017

Hi Svendura,

I am not aware of such modification. I don’t think that can be easily done. It can be annoying sometimes, I must agree.

Cheers,

Svendura

May 12, 2017

The one thing that prevents me from buying the Husky 701 is the location of the filler cap. That is where my luggage sits.

Do you know of a solution to relocate the filler? Maybe sideways like the BMW has it which would be ideal?

Romano Da Deppo

April 12, 2017

Spiegazione ottima, io ho un 690 enduro del 2008 e adesso ho scelto questo upgrade perché il bullone superiore di serie si sta piegando.

Ron Ramsey

December 24, 2016

Excellant explanation. This site and the knowledge of the writer / author is very impressive. He knows his business.

Thank You for the info.

Leave a comment

Comments will be approved before showing up.

Gliga - Perun moto

October 20, 2025

Hi Thao,

We don’t offer lower bolts as a standalone product. You need to order the entire set (upper and lower assembly).

It is currently available at both perunmoto.com and perunmoto.eu websites. Please make sure you chose the correct bike model year when ordering.